This was one of the most influential American companies in the world of botanical architecture. Starting in the mid-19th century, it created majestic greenhouses, conservatories, and glass pavilions that shaped the face of the New York Botanical Garden and others. Read on newyork1.one for more about the history of this pioneering company.

The Birth of American Greenhouses

In the second half of the 19th century, a trend for grand greenhouses spread across the U.S. East Coast after the incredible Crystal Palace—a gigantic structure of glass and iron that impressed everyone—appeared at the 1853 World’s Fair in New York. It was then that a young carpenter from Buffalo, Frederick Lord, realized that greenhouses could become a true art form, not just utilitarian construction. He began creating wooden and glass greenhouses for his neighbors, and by 1856, he founded his own company, Lord’s Horticultural Manufacturing Co., dedicating himself entirely to the craft.

Initially, production was located in Syracuse, but Lord quickly understood that the key customers were wealthy estate owners along the Hudson River. He therefore relocated the factory to Irvington, establishing the main office and production site on the riverbank. Here, amidst the picturesque hills and on plots filled with artificial soil, the first large glass and steel greenhouses appeared, quickly gaining popularity among affluent families.

In 1872, Lord’s son-in-law, William Addison Burnham, joined the business, and the company changed its name to Lord & Burnham. The first large-scale project was for Californian philanthropist James Lick—an enormous glass pavilion covering over $12,000$ sq. ft. ($1100$ m²), whose parts were manufactured in New York and shipped by boat around Cape Horn to San Francisco.

By 1881, Lord & Burnham had built the first curvilinear, steel-framed greenhouse in the U.S. for railroad tycoon Jay Gould at his Lyndhurst estate in Tarrytown. It was a revolutionary structure: fire-resistant, with large glass panels that allowed more light, and featuring a new heating and ventilation system.

The Rise and Fall of a Glass Empire

By 1912, Lord & Burnham had transformed the Irvington factory into a true industrial complex. The factory employed about 250 people, and the new facilities were used for all stages of greenhouse production—from assembling frames to installing glass panels. Demand for the company’s products grew steadily, leading Lord & Burnham to merge with two other manufacturers in 1905: Hitchings & Company and Pierson-Sefton Company. Several more firms were later acquired, including William Lutton Company. The company didn’t limit itself to New York. A headquarters was established in Des Plaines, Illinois, to serve the American Midwest, and a branch was opened in St. Catharines, Ontario, for the Canadian market.

Lord & Burnham didn’t just build greenhouses; they invented new ways to make them true palaces for plants. One of the main challenges was the heating system, so the company actively developed boiler production. By 1917, it acquired a controlling stake in Geneva Boiler Works, and by 1919, it created the separate Burnham Boiler Company, focusing solely on boilers for greenhouses and industrial heating. In 1923, a new foundry and machining shop for boilers opened in Lancaster, Pennsylvania, and the company later acquired several more manufacturers to expand its market presence.

During both World Wars, the factory shifted its focus to military needs. It produced pontoon bridges, hand grenades, and assault boats. After the war, in 1946, all company divisions were consolidated into the Burnham Corporation, which continued producing boilers and greenhouses, implementing new materials and technologies—steel, aluminum, and combined structures. In 1954, the company updated its popular Orlytgreenhouse line, making them more accessible for amateurs and easier to use.

For a century, Lord & Burnham remained innovators in greenhouse and boiler manufacturing, blending aesthetics with engineering ingenuity. But by 1988, the Irvington factory permanently closed, and the legendary company, which once conquered North America with glass palaces, ceased to exist.

Lord & Burnham Masterpieces

Starting with its very first greenhouses, Lord & Burnham experimented with materials and construction. Initially, it was cypress wood, later iron and steel, and by 1932, the first trials with aluminum began for the U.S. Botanic Garden. Commercial use of this metal only became economically viable in the mid-1950s, but these experiments demonstrate the company’s drive for innovation.

Lord & Burnham created a number of outstanding greenhouses that still impress with their scale and beauty today:

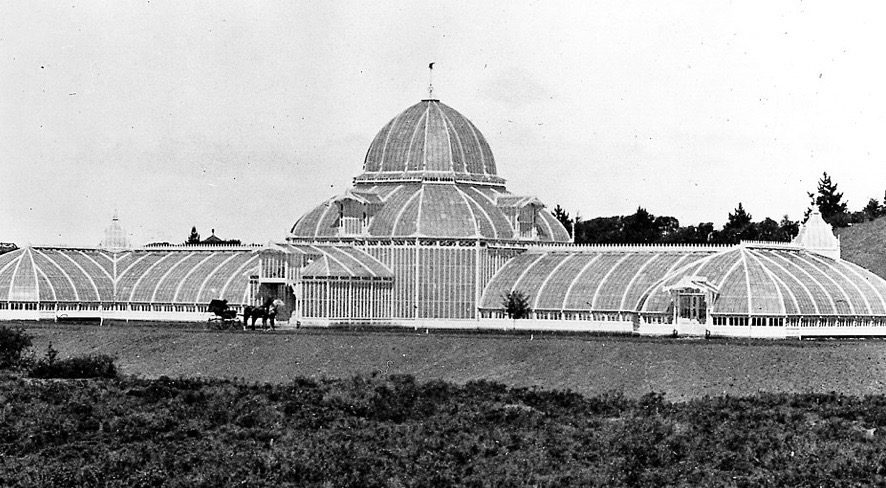

- The wooden and glass flower conservatory at Golden Gate Park, San Francisco (1878–1879);

- Phipps Conservatory and Botanical Gardens, Pittsburgh (1892–1893);

- Buffalo and Erie County Botanical Gardens, New York (1895–1899);

- The New York Botanical Garden (1899–1902);

- Sonnenberg Gardens & Mansion State Historic Park, Canandaigua, New York (1903–1915);

- Reynolda Gardens, Wake Forest University, North Carolina (1912);

- U.S. Botanic Garden, Washington, D.C. (1933);

- Volunteer Park, Seattle, Washington (1912);

- The Krohn Conservatory, Eden Park, Cincinnati (1933), later restored by Lord & Burnham in 1966.

Lord & Burnham didn’t just build greenhouses—they created true architectural masterpieces, combining engineering innovation with aesthetics. Their structures, heating systems, and material experiments became the standard for the American greenhouse industry and remain an important legacy in the field of botanical architecture and engineering design.

The Lord & Burnham Legacy

After the factory closed, the company’s collection was transferred to The New York Botanical Garden, where it preserves the unique history of the American greenhouse industry. This archive contains over 140,000 drawings, plans, and renderings, which reveal the designs for more than 10,000 glass buildings—from large conservatories and winter gardens to solariums, art studios, and aviaries.

The documents were preserved in various forms: pencil, pen, and ink on paper or drafting linen, as well as photos. Although some materials were lost due to fires and flooding at the factory and offices, the archive still allows researchers to trace the evolution of the company’s greenhouse design and technology.

The work of Lord & Burnham lives on. Companies like Under Glass Manufacturing and Rough Brothersproduce greenhouses based on original designs, while Burnham Commercial continues to manufacture boilers. In 2018, Arcadia GlassHouse LLC acquired the engineering and manufacturing assets for Lord & Burnham’s residential greenhouses and continues to produce the original structures and spare parts.

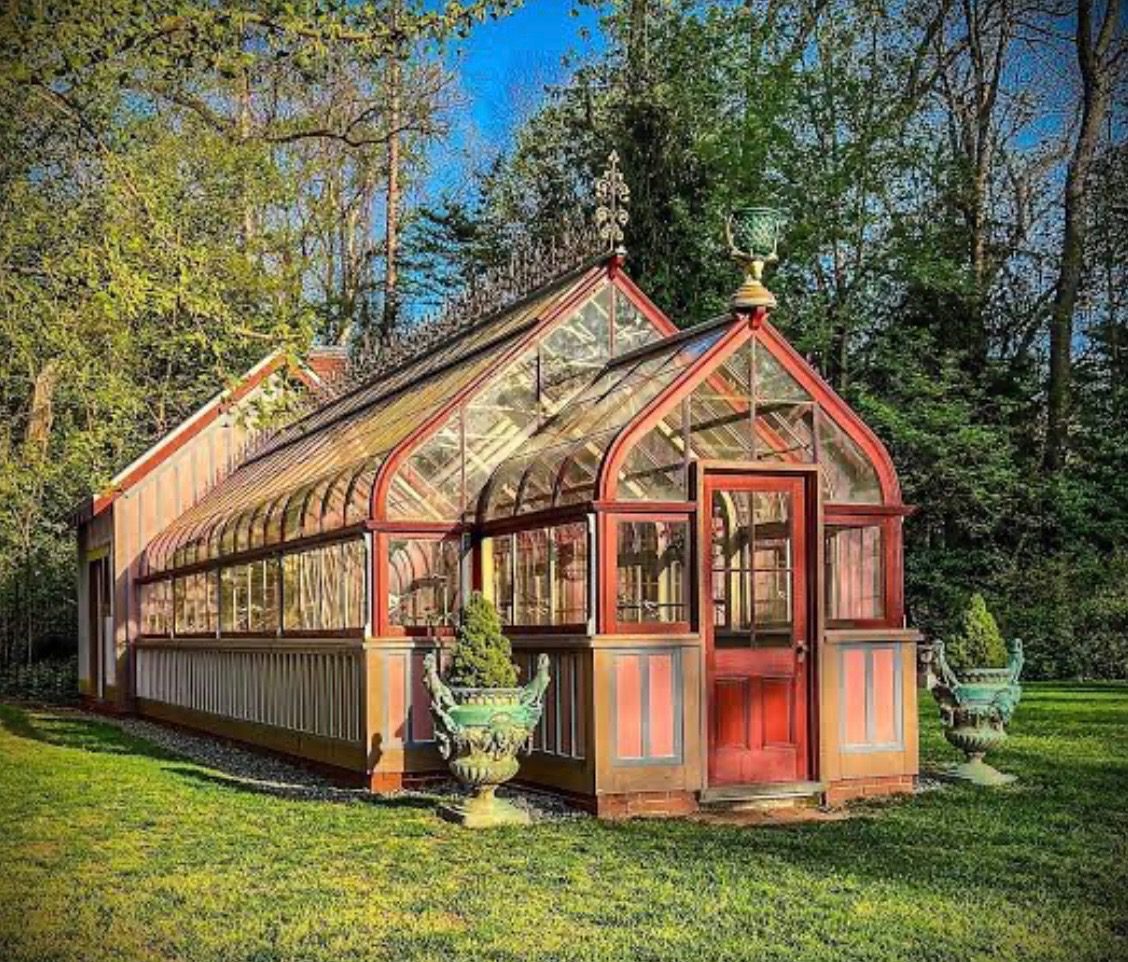

In 2012, one of Lord & Burnham’s legendary greenhouses underwent a major rehabilitation after decades of neglect. During a storm, a tree fell onto the glass structure, damaging the frame, cast-iron gutters, and the shading system. Work continued for years, but by 2022, the greenhouse was fully restored using the company’s original catalogs. It now functions again as a working space for growing plants, bringing the spirit of innovation and craftsmanship back to life.